Total product cost is a cornerstone of managerial decision-making, offering insights that extend beyond financial statements. Managers use this metric to evaluate production efficiency and identify cost-saving opportunities. By analyzing the components of product cost, they can pinpoint areas for resource reallocation or process improvement, enhancing productivity. Standard costing is another approach, using predetermined costs to allocate overhead. It simplifies budgeting and variance analysis by comparing actual costs to standard costs, identifying deviations. For instance, if the standard electricity cost per unit is $5 but actual costs are $6, management can investigate and address the discrepancy.

Who Should You Contact When There Is Overcosting Or Undercosting In Business?

If there has been an overcost or undercost, they can calculate how much money needs to be returned to the company’s account. On the https://mamen69.co/what-is-a-liability-account/ other hand, if your prices are too low, you may find that you’re not making enough profit to sustain your business. Customers might also think your goods or services aren’t as good as your competitors. Cost can increase when there is bad management or poor communication between departments in a company.

- Choosing the right allocation base is crucial for reflecting true production costs and maintaining competitive pricing.

- Customer research may be the most important step in building and maintaining any product.

- There are a few reasons why business owners might undercost their products or services.

- Understanding product cost is critical for making informed business decisions, such as discontinuing a product line or expanding into new markets.

- Royalties owed by natural resource extraction companies are also treated as production costs, as are taxes levied by the government.

How Should Business Owners Set Their Prices?

Production costs, which are also known as product costs, are incurred by a business when it manufactures a product or provides a service. More specifically, production costs are the direct and indirect expenses attributable to a company making a product or furnishing a service. While product costs are directly tied to the creation and development of a software product or technology solution. Period costs are the expenses that a company incurs during a specific accounting period but aren’t directly related to the product’s development.

- You may need to buy state-of-the-art equipment for your developers and other team members.

- To avoid these consequences, it is important for businesses to carefully consider their production cost assumptions and regularly review them to ensure that they are still accurate.

- The direct labor cost will vary depending on the number of workers and the hours worked.

- If you’re unsure where to start, consider using a pricing strategy like value-based pricing.

- These costs consist of direct labor, direct materials, consumable production supplies, and factory overhead expenses.

A. Direct materials

Depending on the company, product managers may or may not determine the pricing strategy for the product. An average product cost per shirt of $103 is then determined by dividing the total annual product cost of $2.23 million by the annual production of shirts. The company should charge an amount higher than $103 per piece of its shirts. By estimating the per-unit cost, the entity can set an appropriate sales price and avoid under-pricing or over-pricing its products. The most crucial step of the whole budgeting process is determining the overall and expected product cost per unit (shirt).

Review your prices regularly

Some cost-saving measures, like hiring junior developers, may result in several issues later on in the product costs consist of development process. You may be envisioning a SaaS product with several features and components. It can be costly to fully build out this level of complex software and maintain it. You’ll also need to consider quality assurance processes and maintenance. Product cost can be recorded as an inventory asset if the product has not yet been sold. It is charged to the cost of goods sold as soon as the product is sold, and appears as an expense on the income statement.

Manufacturing overhead

Historical cost data helps predict future expenses, enabling realistic financial targets and alignment with broader Oil And Gas Accounting business objectives. This data-driven approach allows companies to allocate resources effectively and anticipate financial challenges. For example, anticipating a rise in raw material costs might prompt a firm to adjust procurement strategies or explore alternative suppliers, mitigating potential impacts.

Manufacturing Overhead

In some cases, business owners may also believe they can make up for any lost revenue by selling more goods or services. Managerial accounting refers to a branch of accounting that covers the flow of information internally. This branch covers various tools and techniques that companies can use to enhance decision-making. Learn why a clear narrative drives alignment, investors, and early adopters before OKRs matter. Backing up your assumptions with data can bolster your confidence that you are building a product that actually meets the needs of your customers.

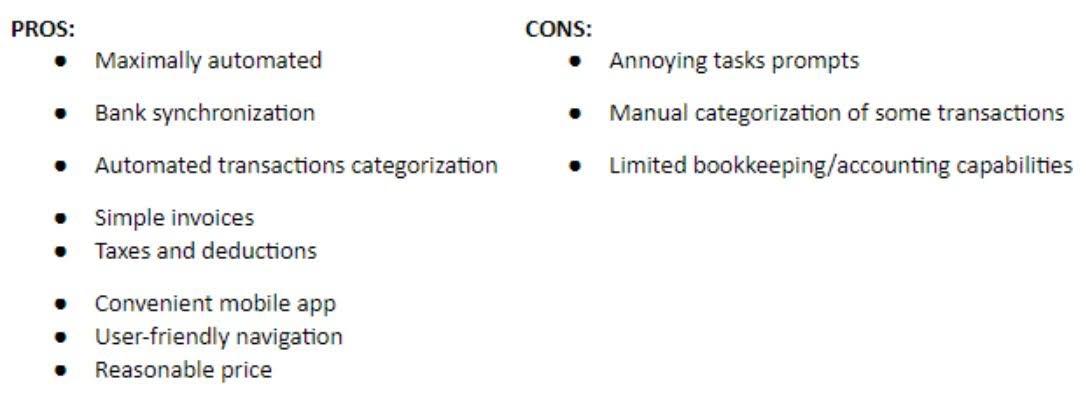

Product overcosting or undercosting is a big problem for most manufacturing companies. It is a problem because they don’t have the right product costing strategy. This post will explain why manufacturing managers should worry about product overcosting or undercosting. The company pays its workers $20 per hour, and it takes two hours to make one widget. Let’s assume the company needs $100 worth of raw materials to make one widget. Product costs are costs necessary to manufacture a product, while period costs are non-manufacturing costs that are expensed within an accounting period.

- Direct materials are those raw materials that can be easily identified and measured.

- To determine this cost on a per-unit basis, divide this cost as calculated above by the number of units produced.

- A bit harder to calculate, time is a crucial factor to consider nevertheless.

- It helps you understand the financial implications of your decisions and accurately assess how much it costs to produce a given product.

- For example, if a product has a high cost and a low selling price, it may be more cost-effective to produce it in large batches to achieve economies of scale.

- Regularly reviewing these variances ensures accurate financial reporting and informed cost control decisions.

Direct costs for manufacturing an automobile, for example, would be materials like plastic and metal, as well as workers’ salaries. Total product costs can be determined by adding together the total direct materials and labor costs, as well as the total manufacturing overhead costs. To determine the product cost per unit of product, divide this sum by the number of units manufactured in the period covered by those costs. Data like the cost of production per unit or the cost to produce one batch of product can help a business set an appropriate sales price for the finished item.